Innovation

New Materials and Qualities

At Refraceram, we work continuously on the development of new materials and ensuring quality.

Collaboration with our clients is reflected in the development of new qualities based on their requirements, a process that begins with laboratory testing and continues through implementation in industrial processes.

The constant monitoring of processes through established quality controls ensures the consistent quality present in all our products.

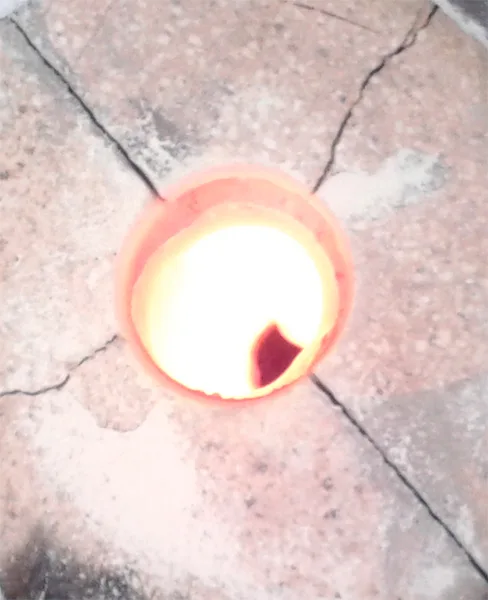

Aluminum Slag Attack Test on Refractory

Simulation of Conditions in Rotary Kiln 1

Simulation of Conditions in Rotary Kiln 2

Study of Glassy Material Penetration on Refractories

Simulation of a Casting Process